What we Expect from Our Knives

Product development at North Arm has several drivers:

- superb level of function

- products that are bought once to last a lifetime

- beauty, style and uniqueness

- connection to the area where we live

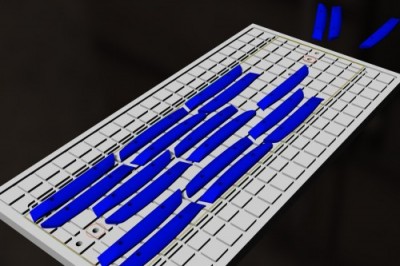

We design and produce our products with the help of technology, including CAD (computer aided design) and CAM (computer aided manufacturing). Working with the appropriate raw sheet stock we cut both blades and handles in small batches using a CNC machine. Each blade coming off the mill proceeds through a multi-stage hand finishing process that involves deburring, polishing, heat treating, buffing, and sharpening before it is ready for assembly with the handle parts. We use only the best cutlery steels available, and the most durable handle materials we can find. Our knives are designed to be technically advanced, functional and attractive. We expect them to grow old gracefully with you while always being a pleasure to cut with.

Our Advantage

The nature of our production methods and our relatively small production scale give us some advantages over large factories. Our methods are relatively flexible compared to big companies whose processes are often tightly bound to specific material properties and for whom production line changes can require years of development. We can adapt our process to use new steels or handle materials with relative ease. That means we can respond quickly to customer feedback regarding design and materials. Being as small as we are, we have decidedly more the feel of a custom shop than that of an massive factory, while being in a position to satisfy a bigger market than a true custom maker. We are able to use superior materials that are less compatible with large scale productions techniques, yet keep our pricing competitive with higher end mass produced knives.

Choosing a Knife

Choosing a knife depends primarily on what the user wishes to cut with it. Blade geometry plays a large role in the way a knife cuts. Geometry is the shape of the knife’s blade, namely the profile and cross section. A knife with a thin spine that tapers very gradually to a fine cutting edge will be an excellent slicer but also relatively delicate. On the other hand a knife with a thick spine which tapers to the cutting edge over a short distance will be very strong, but won’t be as good slicer. A knife’s intended use can be determined by observing its geometry so pay close attention to this aspect when knife shopping. Each of our knives has an intended use and blade geometry to match.

Equally important to geometry is steel quality. Not all steels are created equal. Far from it in fact. The chemical composition of steels is what sets them apart from one another. If a manufacture won’t tell you what type of steel the knife is made of, or simply calls it “stainless steel”, “surgical steel” or “high carbon stainless steel,” it is almost certainly a poor one. Those are very loose terms which manufacturers spin to make the sub-par steel in their knives sound high end. Any reputable knife manufacturer using high quality steels, will advertise the specific grade of steel used in a knife, as a point of pride. For example, we use CPM S35VN in all our blades. Steel is the heart of a knife; when you are considering buying a knife, whether from us or another company, do some of your own research on the steel before commiting to the purchase. Carbon content is one of the best indicators of the quality of the steel, the best steels are made up of 1% carbon or more. Other good things to look for are Vanadium and molybdenum content.

Our Lineup and Roadmap

We make knives for the kitchen, the outdoors and the pocket. Details on the specific models can be found in the product pages in our online store.

We’re always re-evaluating our product development plans, tweaking priorities based on customer demand and our own sense of what the market wants.